Boom Supersonic Deploys ODiSI System for XB-1 Prototype Testing to Build World’s Fastest Supersonic Jet

The last commercial supersonic flight was more than 16 years ago, and due to cost, safety, efficiency, and environmental sustainability challenges, airlines have not rushed to re-enter this market. But Luna customer Boom Supersonic is bringing supersonic commercial air travel back! The company recently announced that it will roll out its XB-1 prototype on October 7 and begin test flights in 2021.

The XB-1 prototype is a 1:3 scale of its supersonic commercial jet “Overture,” which is being developed with composite aerostructures and high-temperature material systems. These materials, which have only recently been accepted by the FAA for use on commercial aircraft, will make supersonic flight more fuel efficient with a smaller noise footprint.

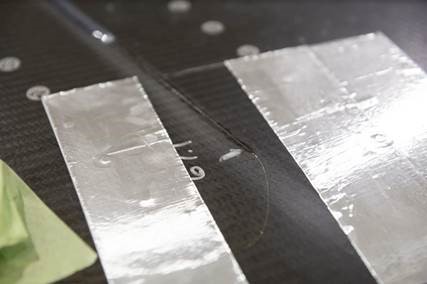

As part of this development work, Boom used Luna’s ODiSI (the industry's only high definition fiber optic sensing solution) alongside standard foil gages on the wing skin of the XB-1 during recent static tests.

The sensor paths were designed to traverse and trace the underlying titanium or carbon-fiber composite wing spars, which are often referred to as the “backbone” or “skeleton” of the wing and give each wing the strength to take the bending load for lift. Each wing spar path was instrumented with an individual fiber optic sensor to measure the strain.

of the wing spar

Small, low-profile, lightweight, high-definition fiber optic sensors deliver thousands of measurements on a single optical fiber. With high spatial density and the ability to measure difficult geometries and locations, these fiber optic sensors can map strain in hard-to-reach areas with high strain gradients. In addition, ODiSI can be used to validate and calibrate modeling outputs and be easily integrated into larger test management platforms.

In addition to the hardware, Luna also provided training to the Boom team on handling and installing sensors, as well as generating an interactive, touch-to-locate map to reference the location of the fiber gages relative to their physical location on the spar paths and matching foil gage locations. Luna’s team also provided instruction on setting up the ODiSI HD-FOS system for data logging and interpreting the data output.

Due to the intuitive user interface and ease of setup and use, the Boom team was able to conduct the testing and collect the multichannel HD-FOS measurements without much additional support. Furthermore, the flexible, lightweight and easy-to-install sensors reduce time-to-first-measurement and greatly reduce overall cost-of-test relative to implementing an all-strain-gage approach.

After the successful wing spar testing, an additional modality for sensing was quickly implemented on the vertical tail as well, due to the ODiSI’s ease of use and the collaboration and training from Luna’s engineers.

Learn more about HD-FOS and Luna’s ODiSI system.