Measuring Uniformity of Cure Temperatures Using High-Definition Fiber Optic Sensing

The use of composite materials is ever increasing due to their high strength to weight ratios, manipulative properties, multifunctional capabilities and corrosion resistance. To fabricate high-quality composite components with acceptable thermal properties, elevated temperature cure cycles are typically required. Maintaining uniform heat distribution throughout the curing composite can be critical to the performance of the resulting part.

Thermocouples are typically used to both monitor and control the cure cycle. Multiple thermocouples are necessary to measure both air and part temperature at critical locations. The logistics of installing, wiring and tracking each sensor can be cumbersome, especially with complex parts.

An alternative to multiple thermocouples is the use of High-Definition Fiber Optic Sensing (HD-FOS) to measure the temperature during the cure cycle. In combination with Luna’s ODiSI interrogator system, temperature can be measured with high spatial density (millimeter resolution) along meters-long sensors, enabling temperature profiling across an entire part as opposed to obtaining measurements only at discrete locations.

An alternative to multiple thermocouples is the use of High-Definition Fiber Optic Sensing (HD-FOS) to measure the temperature during the cure cycle. In combination with Luna’s ODiSI interrogator system, temperature can be measured with high spatial density (millimeter resolution) along meters-long sensors, enabling temperature profiling across an entire part as opposed to obtaining measurements only at discrete locations.

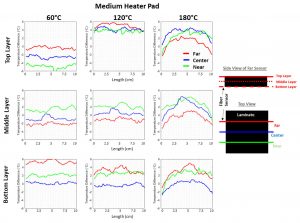

Luna is presenting a technical paper on “Measuring Uniformity of Cure Temperatures Using High-Definition Fiber Optic Sensing" at CAMX (The Composites and Advanced Materials Expo) this week in Dallas, Texas. The subject of this paper was an initial investigation into the application of HD-FOS temperature sensors to the thermal uniformity of heat pads used for the composite cure cycle of an Out of Autoclave (OOA) prepreg system. HD-FOS sensors were applied in a serpentine pattern in three layers of composite laminates during lay-up and monitored during application of heat via heat pads. The work demonstrates the ability to measure spatially dense temperature distribution on, inside and under a composite panel during the cure process.